The In’s and Out’s of Lab Incubators

Amanda2021-10-14T17:45:08+00:00What is an incubator?

Incubators are the mainstay of just about any laboratory, research facility, hospital, even zoos, and farms! For most of us, our first exposure to incubators and incubation happens in elementary school when we learn about the growth cycle of a chicken egg.

A small incubator or a simple heating lamp is brought in, fertilized chicken eggs are carefully marked and laid out, the heating begins and then we eagerly await the result. We’re told the heat provided by the lamp or instrument mimics the warmth of a mother hen and we learn about how conditions must be just so to get a result.

This is the core principle of scientific incubators; controlled environmental factors designed to yield, we hope, a particular outcome. Over the years, incubator technology has grown and the range of controllable factors has expanded, so now, just about any variable you want to manage is possible.

What does an incubator do?

Incubator comes from the Latin word, incubatio, and translates to brooding. The idea is to apply sustained favorable conditions to something, bacteria, cellular cultures, embryos, plants, even antibodies, to stimulate growth. The stable, contaminant-free environments are optimized for not only growth but also storage.

Incubators as an instrument came about in 1880, as a means of reducing the mortality rate of premature infants. A french obstetrician named Dr. Tarnier observed warming chambers at the Paris zoo as having benefits for poultry and applied the idea to premature infants in his charge.

The warming helped the premise with thermoregulation issues they faced and saved many lives. Soon thereafter these newly dubbed incubators made their way to the 1896 World Exposition in Berlin and eventually to the Coney Island Boardwalk as both an attraction and innovative healthcare.

Incubators vs Lab Ovens vs Lab Furnace

Incubators are not to be confused with a lab oven. While they operate with the same controlled and sustained heating principle, these two serve very different purposes. It’s important to understand your needs before buying an instrument so you don’t end up with something you can’t use.

Incubators generally run between 30°C, sometimes lower, and up to around 60°C. A lab oven, however, tends to run much hotter, with a range between 70°C up to 250°C or more. Higher than 300°C and now you’re looking at lab furnaces, or muffle furnaces. These high-temperature ovens are made for metal studies, identifying organic and inorganic substances, sterilizing, and polyimide baking.

These higher temperatures remove moisture and are ideal when you’re intentionally trying to dry something out, or test artificial component tolerance, or perhaps sterilize an object. As such a lab oven or a muffle furnace is not ideal for work with live materials.

How does an incubator work: Heating methods

There are two methods of dispersing heat in a laboratory incubator chamber, gravity convection or forced air circulation. Gravity convection incubators rely on physics to distribute heat, hot air rises and cooler air falls, with the added benefit that there are no air currents to disturb a culture. Forced air incubators use a fan to distribute temperatures around the chamber, and have excellent temperature uniformity, but could result in a higher risk of drying.

Incubator construction and features

Aside from just heat, there is a range of options that modern incubators can control. Choosing the right incubator for your application means you have to consider your ultimate goal and narrow your range of choices. Choices such as, do you need CO2 control, and if so which sensor is best for you? Do you need O2 control for in vivo conditions, or do you require contamination controls like HEPA filtration, antimicrobial copper interiors, or high-temperature sterilization?

Another consideration is incubator size. Do you only need something that is compact and can fit neatly on a benchtop, or something with a high capacity, such as a stacking incubator set or a reach-in incubator model?

Do you need to operate additional equipment? Some lab incubators also feature ports and outlets allowing you to have instruments like stir plates or shakers, within the chamber while running.

How the incubator is insulated can be another important factor to consider. Options include water-jacketed incubators where a wall of water helps maintain temperatures in the event of a power failure. These can provide peace of mind that your samples are protected, however, you do not have the option for high-temperature decontamination that you get with an air jacketed or fiberglass insulated direct heat model.

Types of incubators

On top of the heating options provided by a general lab incubator, users can drill down into the bevy of other conditions an incubator can control.

Gas incubators allow for direct control over how much of and when gas is added to the environment. The most common addition is CO2, and for applications where a hypoxic condition is needed, then a tri gas or multi-gas incubator would be used for additional O2 control.

Environmental Chambers, Humidity Chambers, and Climatic Chambers allow for the control of not only CO2 and at times O2, but also tight control of humidity levels. These tend to be larger scale but give you flexibility over how much and when humidity is distributed within a run.

If your needs require temperatures below 30°C, then a refrigerated incubator is right for you. Cooling incubators and BOD incubators, (biological oxygen demand), allow for studies optimized for either growing or preventing growth. These are cooled with either a compressor system or a Peltier system.

Other types of incubators include shaking incubators where samples are agitated while heating and hybridization incubators that add humidity control in addition to heating and agitation control.

Plant and insect studies benefit from growth chambers that incorporate a lighting control on top of temperature, gas, and/or humidity control. By being able to set how long and when light is added, users can mimic day and night cycles, no matter the actual time of day.

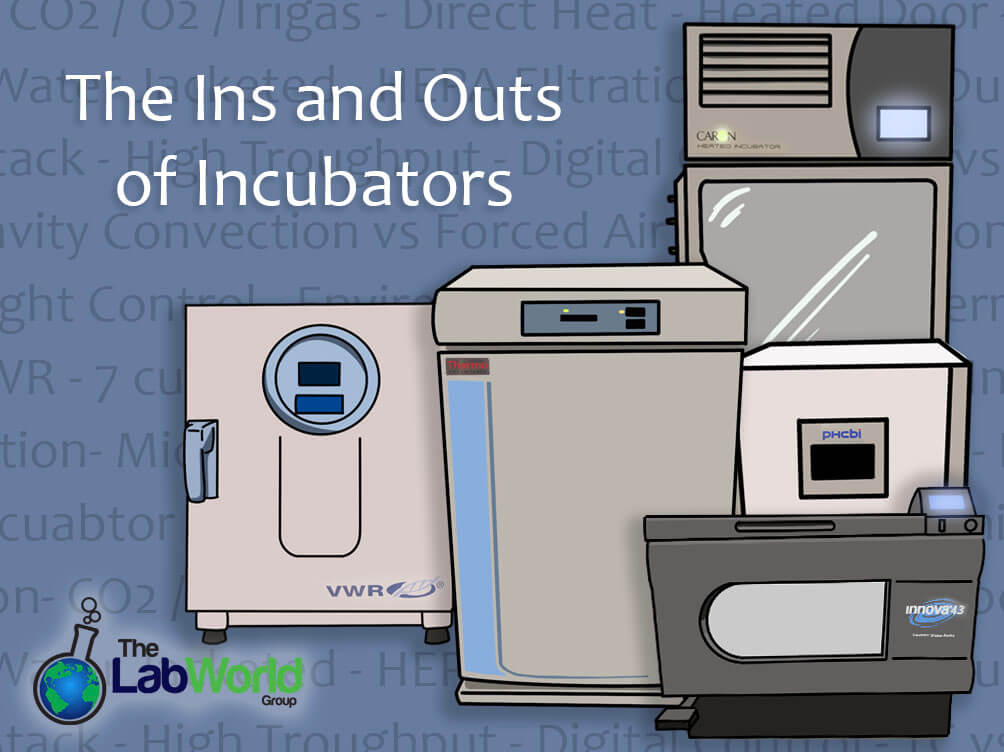

Incubator Manufacturers

There are many incubator manufacturers out there, and each has a proven track record with reliability, quality components, and mindful design.

Thermo Scientific and Fisher Scientific have been making and innovating the incubator design for decades. This manufacturer produces mainstays such as the Heracell series, and the ever-popular Forma Series II 3110 CO2 incubator. Not only are they dependable but they also have a wide selection of options so you can choose the right components to fit your needs. They carry an option for just about every incubator laid out above.

PHCBi, once operating under the well-known banners of Sanyo and Panasonic, also has a reputation for excellent construction. They not only carry a variety of sizing options to meet your needs, but they have also added innovative technology such as inccusafe, a copper-infused alloy interior chamber, giving you the antimicrobial properties of copper without the maintenance.

NuAire CO2 incubators use infrared CO2 sensor technology, and separate chamber and door heaters to give you controlled uniformity. Additionally, they feature ISO 5 level filtration and digital control with the option to download data and documentation.

Incubators from VWR cover sizing from compact personal incubators that can be kept nearby, all the way up to high-capacity reach-in incubators and everything in between. These reliable instruments can feature refrigeration, CO2 control, water jackets, gravity convection, precise digital control, and user-friendly interfaces, you name it, VWR has your need and price point covered.

Other top manufacturers include Binder, with innovative heating and cooling technologies that are energy efficient and highly accurate, and Caron with its comprehensive line of test chambers and growth chambers. Caron incubators focus on high throughput, high accuracy, and tight control, with each ideally tailored to specialized applications like animal rearing, or photostability.

Final thoughts

Sorting through the options when it comes to types of incubators can be a challenge. The best place to start is thinking about what your ultimate goal is. From there you can work your way back through options and sizing, degrees of control needed, and what your overall budget will give you.

Buying an experienced instrument from a reputable dealer, like The Lab World Group, means not only can you stretch your dollar further, but you also benefit from over a decade of experience. From servicing, calibrating, and maintaining these laboratory staples, but more importantly, helping teams find the right fit. Each lab incubator that comes through our door is rigorously tested and validated before it makes it to sale with a clean bill of health.

Let us help you narrow the field of options and find the right incubator to fit your needs.