A Brief History Of Autoclaves

Amanda2024-02-01T16:43:57+00:00Brief History Of Autoclaves

Dr. Charles Chamberland is credited with inventing the modern autoclave in 1879, but to understand how he got there, we must look at the research he worked on with Dr. Louis Pasteur at the Pasteur Institute. Pasteur and Chamberland were studying chicken cholera and anthrax, which were killing large numbers of animals in French agriculture. Chamberland discovered that some porous materials, such as porcelain, can keep hold of fine particles in suspension when slightly heated. This major discovery led to significant advances in sterilization and disinfection.

During his research, Chamberland realized that in order to kill certain spores, it was necessary to heat the liquid to 115°C and hold it for at least twenty minutes. This realization about heat and time would lead to his research project that resulted in the first autoclave.

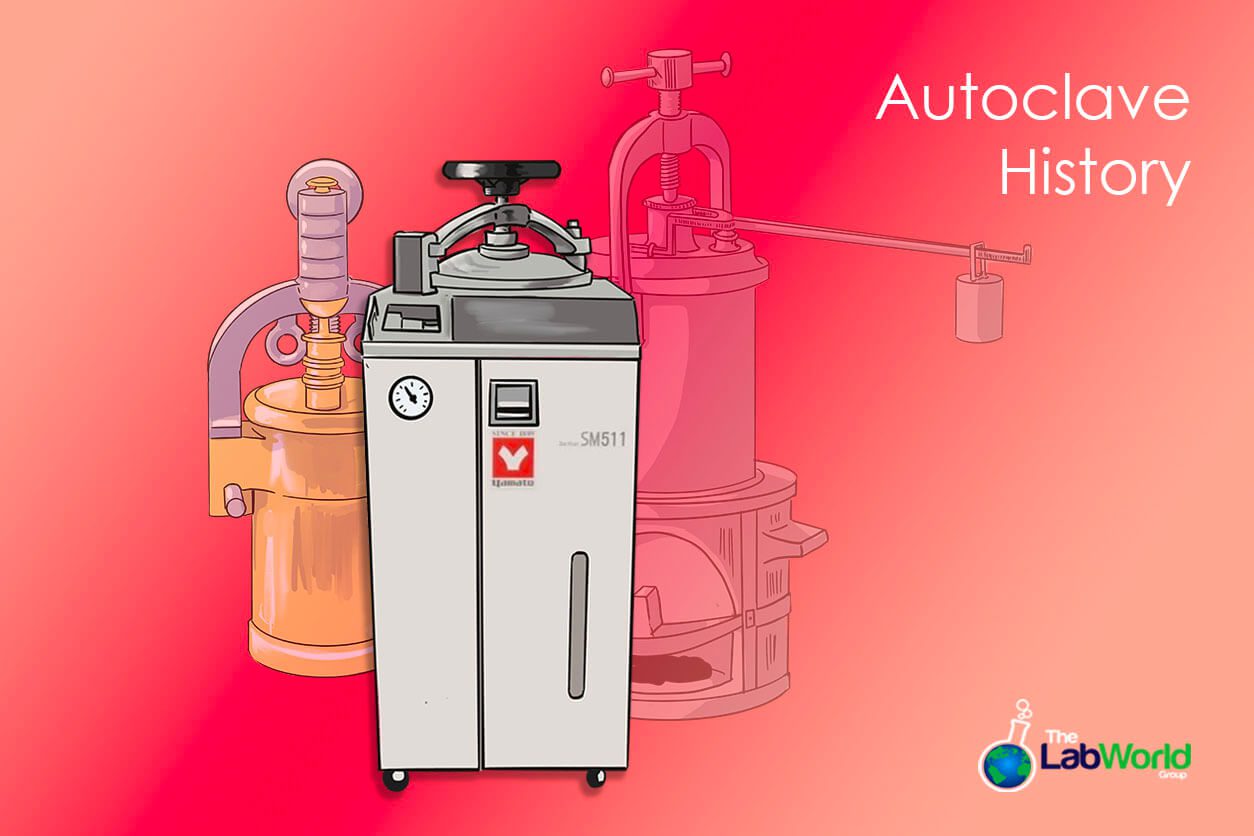

Autoclaves in history

The science of sterilization and disinfection began with Robert Koch in 1881 and his research into the disinfecting properties of steam and hot air. He showed that moist heat (steam) has a much greater penetration power than dry heat. The effectiveness of the moist heat is one of the basic principles behind the autoclave, which uses steam under pressure to disinfect items. Drs. Pasteur and Chamberland expanded on his work in a way that led to the invention of the autoclave. Combining the disinfecting power of steam with high atmospheric pressure resulted in a system that could sterilize items very quickly and effectively.

Denis Papin and the “Steam Digester”

The precursor to the autoclave was essentially the same as a modern pressure cooker – known as the “steam digester.” The steam digester was invented in 1679 by a French physicist named Denis Papin. His steam digester consisted of a tightly sealed vessel that contained steam until high pressure was achieved. It was the first pressure cooker to feature a safety valve – if the pressure became too great in the chamber, the steam would be released, preventing explosions. His design was impractical and flawed but was improved by future engineers, including Dr. Chamberland. Without Denis Papin and his steam digester, we would not have the autoclave we know today.

Evolution of the autoclave

Charles Chamberland’s original autoclave was a gravity autoclave; steam entered the chamber and rose, slowly forcing the denser air out through a vent in the bottom. There have been many improvements to the design of the autoclave since Chamberland’s time, as well as different types of autoclaves.

As the autoclave evolved, one improvement was the ability to utilize steam pulsing. Steam is injected into the chamber intermittently (or pulsed), and the force of the injection pushes the steam into porous or irregular areas it might otherwise not have reached.

Another innovation was the vacuum system autoclave. These autoclaves use a vacuum system to pull out all the air and achieve pressurization. In fact, most modern autoclaves have some form of a vacuum system to force air out and release steam when the cycle is complete.

Autoclaves are primarily used in laboratory or medical settings for sterilization, but autoclave applications have also been shown to be useful in other industries. Industrial autoclaves are used for pressure-treating lumber and vulcanizing rubber for car tires. They can also be utilized to cure and strengthen composite parts that are to be used in harsh environments.

Modern Autoclaves

Autoclaves have come a long way since their inception in the 1800’s. Today’s autoclaves have safety features that prevent over-pressurization or explosions, digital displays, and monitoring systems for every part of the sterilization process. Rubber seals and advanced door latching systems have been added to improve pressure and temperature control. Autoclaves are now available in various sizes, from small enough to fit on a benchtop to autoclaves that must be built into a wall. Vents and drains are equipped with sensors that respond if the temperature or pressure is too high and can automatically release steam or pressure.

Conclusion

The autoclave has become a vital part of many laboratories, medical facilities, and industrial applications. Steam sterilization ensures that any harmful bacteria, fungi, spores, or pathogens are absent on any equipment. As use cases expanded, so did the sizing, features, and safety measures, so no matter your need, there’s an autoclave to match.

At The Lab World Group, we have sold and are familiar with leading autoclave brands. Brands such as Yamato and Tuttnaeur, Sanyo, Fisher, and Tomy each with their own unique features and benefits. Please feel free to contact us to learn more about autoclaves and let us connect you with the right tool for the job.