Bioreactor Applications

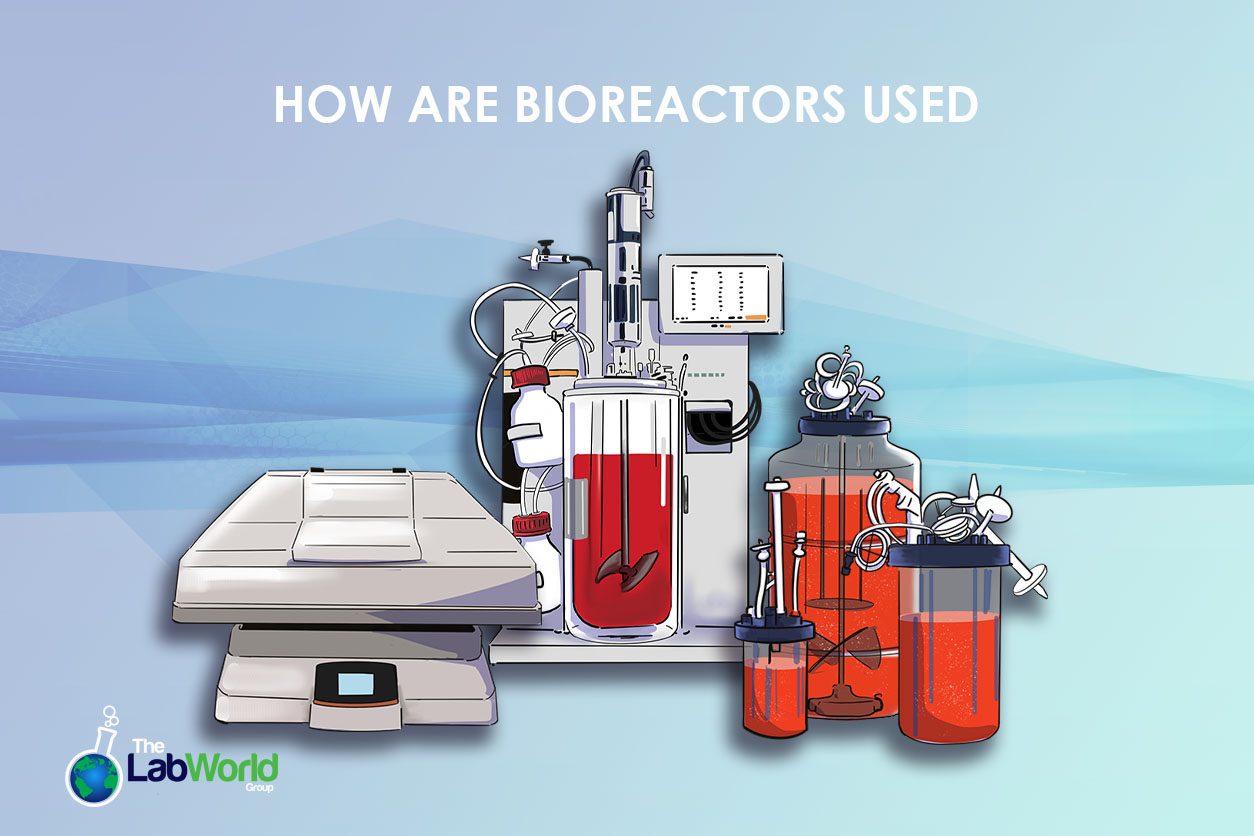

Amanda2024-07-22T17:54:32+00:00When you think of a bioreactor in the lab, you’re probably thinking of pharmaceutical and biotechnology applications. A bioreactor, by nature, is built for growing and culturing cells. It is an integral part of efficiently creating vaccines, enzymes, and antibiotics, but here we’ll look at other novel applications of these instruments.

Bioreactors and Biofuel

The Weizman Process, developed around World War 1, generated a reliable source of acetone, butanol, and ethanol from starchy carbohydrates like corn and grains. This method fell out of favor as the 1950s brought about a fascination with petroleum-based products. When it became clear that fossil fuel supplies are, in fact, finite, there was a renewed interest in biofuel.

Bioreactors such as stirred tanks, batch types, packed beds, and photosynthesis reactors help to produce high yields of biofuel with low shear stress, better mixing, and more efficient use of resources. Microorganisms feed and ferment sugars from biomass broken down into simpler sugars through hydrolysis.

Biodiesels made from used vegetable oils and animal fats are biodegradable, cleaner when burning, and can be used in diesel engines. Ethanol, most commonly derived from corn in the US, can be blended with gasoline to increase efficiency and reduce monoxide pollutants. Hydrocarbon fuels are nearly identical to petroleum-based fuels and can already be used in today’s combustion engines. As research progresses, scientists are looking to convert waste products, cellulosic biomass, and algae to make one-to-one substitutions for petroleum products.

Bioreactors in the Food And Beverage Industries

As we mentioned before, early food preservation efforts were among the first bioreactors in human history, developing alongside civilization. From the first yogurts and beer to bread and cheese, we’ve leveraged microorganisms to help preserve food and improve taste and beneficial attributes like gut health. Bioreactors today are used much the same way in the food industry but on a large scale, making beer, giant vats of kimchi, and sauerkraut.

In recent years, bioreactor technology and advancements have ushered in a new age of food and beverage development, including cultivated meat. Cellular agriculture still feels like science fiction but has become an intriguing means of creating a sustainable and ethical food supply. Meat grown in a bioreactor doesn’t require excessive resources, creates nitrogen runoffs that damage water supplies and ecosystems, and doesn’t produce greenhouse gases. Producing meat in a controlled environment reduces the risk of foodborne illnesses like e. Coli, Trichinosis and Listeria. Plant-based “meat products” taste more like meat thanks to the addition of animal hemoglobin grown in a bioreactor, giving it a more authentic meat flavor.

The biggest challenge facing the development of cultivated meat is scalability. Cultivated meat is expensive, and traditional stir tanks don’t produce enough efficiently yet. Researchers in Europe are working on a packed bed bioreactor system designed to bring manufacturing costs down to get closer to cost parity.

Environmental Biotechnology Bioreactors

As industrial processes have grown in the latter half of the last century, so have the byproducts from manufacturing. These byproducts, such as toxins, antibiotics, and nitrogen, enter our water systems. It is becoming increasingly important to find a way to neutralize these conditions, dealing with them economically, efficiently, and ecologically soundly. Bioreactors of some form have been used in waste management since civilizations began to assemble. However, since the industrial age began, instead of fecal material, we have had to manage modern contaminants such as personal care products and pharmaceuticals, heavy metals, pesticides and cosmetics, synthetic dyes, and plastics. These contaminants, now found commonly in our aquatic systems, are a massive cause for concern.

Bioreactors can be leveraged to treat our waterways with minimal chemical intervention. Bioreactors like airlift, fluidized beds packed bed reactors, and biofilm reactors can help remove volatile organic compounds, pesticides, and heavy metals like copper.

Tissue Engineering In Medical Applications

Bioreactors are ideal for medical applications like tissue generation. They can be tightly controlled and monitored throughout the process and be kept sterile. Tissues generated in a bioreactor can range from cartilage and lung tissues to gastrointestinal tissue, even cornea tissues. Cells are grown on a porous and biocompatible scaffold, and the bioreactor is fine-tuned to create the optimal growth environment. We’re away from growing whole organs or regrowing a bone, but as bioreactor technology gains more complexity, we’ll start seeing more paths toward regeneration.

Conclusion

Bioreactors are a fascinating division of scientific instruments that can take many forms and seem to have more and more applications as the years go by. These novel approaches and applications were used to harness the power of the microscopic world. Scientists are even using bioreactors to grow bacteria and enzymes that could help with our plastic problem; research is in its early stages but showing promise.

A bioreactor is a great way to develop processes and explore other solutions microorganisms can provide to our everyday lives, not only as therapeutic tools but also to address environmental concerns and world hunger. If a bioreactor is in your lab’s plan, let us help you find the right tool. We’re familiar with lab-scale bioreactors, stirred tanks, and wave rockers at the Lab World group. Contact us today to see how we can help.