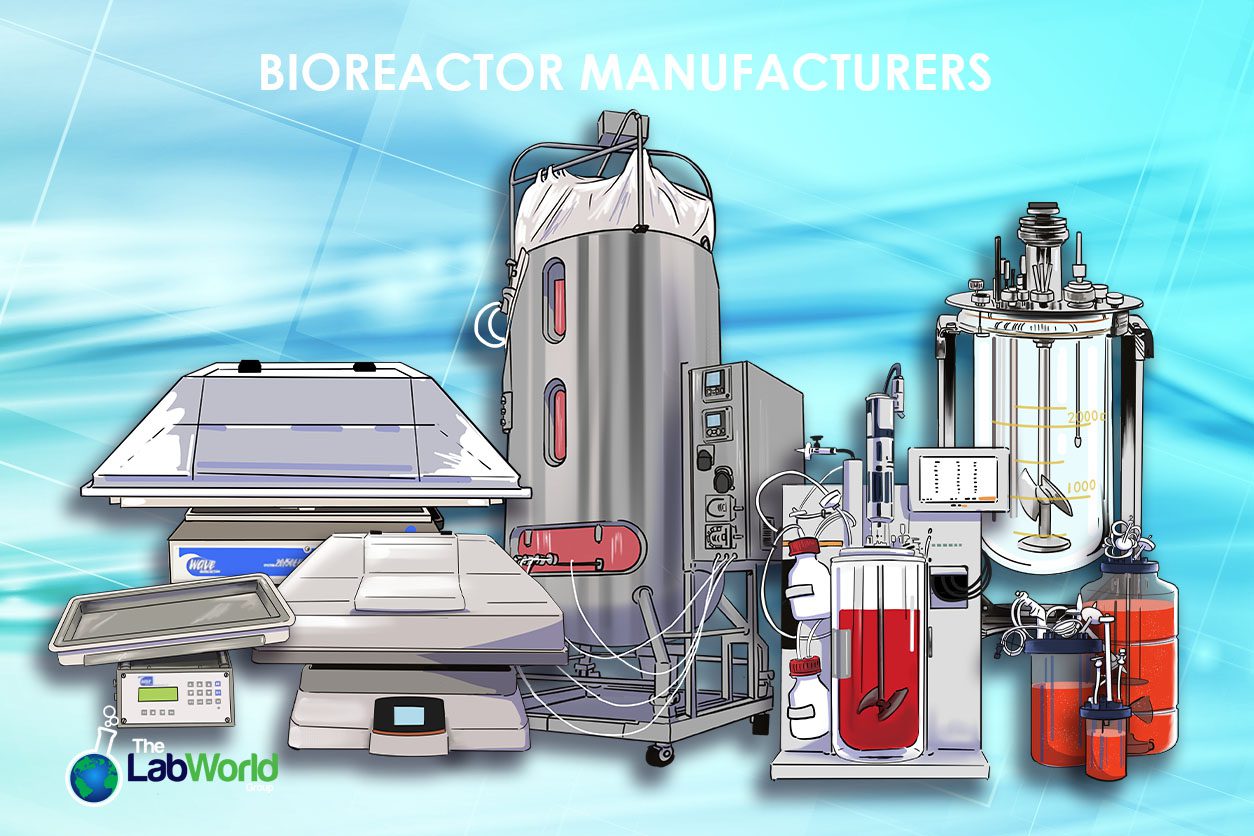

Bioreactor Manufacturers

Amanda2024-05-24T14:38:50+00:00Now that we’ve covered bioreactors and their uses let’s look at some of the top manufacturers. Many have been making bioreactors for years, and each brings their innovations and benefits to the process, from ease of use to scalability to creative and flexible build-out solutions. Below are just a few of the stellar companies out there.

Cytiva Life Sciences

Cytiva Life Sciences offers a full range of cell culture options. After being acquired by Danaher in 2020, G.E. Healthcare was rebranded as Cytiva, bringing a solid portfolio of Wave Bioreactor instruments. Among these is the Wave 25 bioreactor, a ready-to-process system built with dual-zone temperature control that allows two single-use bags to be processed at different temperatures. These single-use bioreactors are ideal for upstream processing and seeding cell cultivation. They can be used with components like gas and concentration monitors and pumps for feeding control. Cytiva also offers consumables for cultivation, such as buffers, process liquids, cell cultures, serums and media, and much more.

Millipore Sigma

Millipore Sigma is the life sciences branch of the chemical company Merck. This biopharmaceutical powerhouse has solutions for each step of the manufacturing process, from upstream processing to harvesting and downstream processing. Millipore Sigma’s line of Mobius Stir Tank bioreactors covers your needs from bench scale at 3Liters to full-scale production at 2000 liters. The technology is designed to make transitioning from development to production seamless. Each of the Mobius offerings is integrated with the sensor-ready control system that monitors and controls the bioreactor. From there, users can control temperature, impeller speed, sparger flow rate, and more.

Eppendorf Bioreactors

Eppendorf is another company that offers bioprocess solutions for large-scale batch production and research and development. The DASbox mini bioreactor system is built for early development applications, giving users multiple channels to develop their optimal processes. The D.A.S. box system can control up to 24 parallel units from the user-friendly software system. At total capacity daisy chained together, these compact systems take up only 6 feet of bench space, allowing users to test it with autoclavable glass units or single-use vessels.

Sartorius Bioreactors

Also in the multi-parallel bioreactor vein is the Ambr from Sartorius. These benchtop systems are ideal for finding a cell line, allowing users to work with up to 48 cultivations of insect and mammalian cultures, with the added feature of automated liquid handling. This bioreactor’s compact size allows it to fit in a Biosafety cabinet for aseptic operation. Such high throughput will enable users to weed out lower-quality clones, feeds, or media before scaling up a process. Because this bioreactor system works with single-use vessels and automated liquid handling, hands-on time, turnaround, and human error rates are significantly reduced.

Thermo Fisher Bioreactors

In addition to rocking or wave bioreactors, Thermo Scientific offers a line of large-scale S.U.B.s that can be configured for continuous processing. These tanks are meant to reduce the space required by permanent tanks, which can take up multiple facility floors and are expensive to build and clean. Their HyPerforma system comprises a support structure with mixing motors, load cells, and a heating system. It is partnered with a bioprocess container with an agitator assembly, sparger, ports, and everything else required.

Other notable manufacturers include Infors HT, which has a sleek benchtop, pilot bioreactors, and sophisticated monitoring. Esco Vaccixcell works with Tide Technology and provides a surface-supported means of working with adherent cells. The gentle up and downward motion of the culture medium in a vessel reduces the surface area needed for adherent cells in a packed bed bioreactor, providing high aeration, high nutrient exchange, and low shear stress. Other steadfast companies like Pall, Lonza, and Solaris have solid offerings.

Conclusion

Bioreactor technology and innovations continue to grow, but principles remain the same. Wave bioreactors are a simple-to-use choice ideal for vaccine production to C.H.O. cells and culture work. The stirred tank remains one of the most popular designs.

No matter your needs, there is a bioreactor and peripheral equipment to meet them. Let us help you find your ideal fermentor to start your discovery process. Buying gently used and vetted bioreactors saves you money and can help scale up production or allow you to find your cell line faster. Contact us today for more information.