A Guide to Laboratory Chillers

Amanda2023-03-17T13:24:02+00:00How the Lab Chiller came to be

Various methods of controlling temperatures in the lab through mediums like water have been in use for hundreds of years. A laboratory chiller for example operates by removing heat from an object by transferring it to another, usually via a liquid. At first ice baths were standard, with 1851 bringing about the first ice machine. Salts could be added to water to depress the freezing point but this proved difficult to control.

A quarter of a century later Carl Von Linde developed a method of liquifying large volumes of gas and paved the way for more modern refrigeration. This then leads to the first centrifugal water chiller, using a compressor. Over the last 200-plus years, chillers have evolved beyond ice baths adding features like single or double compressors, circulation control, and digital programming.

What are lab chillers used for?

Temperature control in the lab has many uses, from everyday procedures to exacting control requirements to keeping equipment from overheating. Operating above or below room temperature requires a method of control that can be steadily maintained for prolonged periods. One of the most effective and cost-efficient ways to achieve this is a recirculating chiller. Chillers have found a home in multiple fields, not just in the lab, with uses in industries such as welding equipment and machine tooling, airconditioning, and dehumidifiers, analytical equipment, or condensing vapors.

Lab chillers help maintain the accuracy of an experiment by eliminating a point of variation. Certain chemical reactions can only take place or may react differently at a set temperature. Not only that but they help to cut down on water waste by conditioning and recirculating the same water, saving tens of thousands of gallons. Lab chillers can be used to quickly drop a temperature or gently thaw a sample from deep freeze Depending on the degree of control you need, some applications are tolerant of a little variation so analog control can be enough. Applications where precise control within a degree is needed, then microprocessor control with feedback monitoring can provide info on not only your set point but the actual temperature and record the process for reporting.

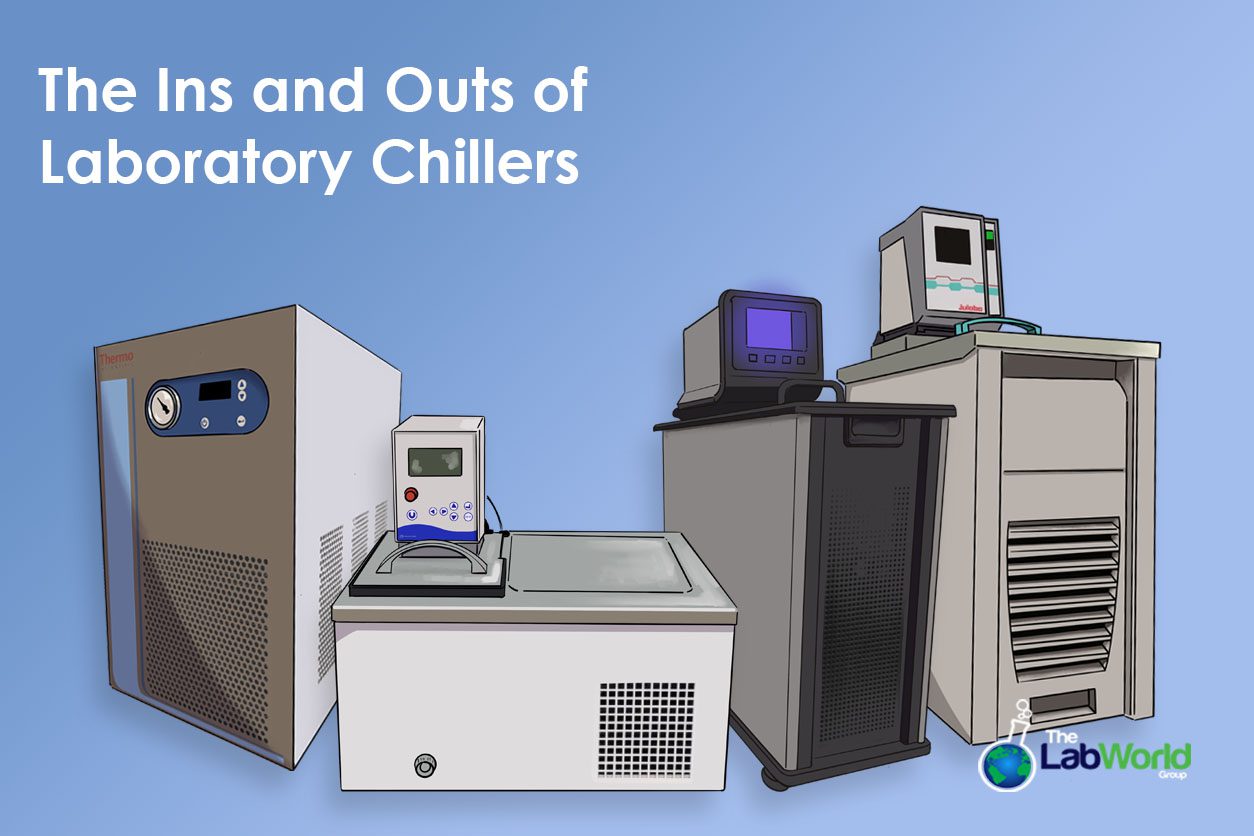

Types of Lab Chillers and Their Limits

Choosing a laboratory chiller is based mainly on how low you need the temperature to get. After that, you’ll want to have a clear picture of what you’re chilling and how large or where you need the capacity to be. Lab chillers can operate in two ways.

Immersion chillers are coils of metal either stainless or copper with water running through them continuously to draw heat away. These can be dropped into a circulating or immersion bath. Immersion circulators can be cost-effective, take up less space, and are flexible in placement, however, they are limited in their flow rate and cooling capacity.

A recirculating chiller can sometimes have an integrated bath for direct immersion or be set up for a closed or open loop system for external applications, or both. These chillers feature a pump and a built-in refrigeration system Recirculating chillers usually feature one or two condensers depending on how low a temperature it needs to reach. Recirculating Chillers can heat or cool, and depending on the medium used can cool to temperatures as low as -90°C. To reach such low temperatures, the use of specialized fluid such as ethynol is needed.

Manufacturers of lab chillers and circulating water baths

There are many reliable manufacturers of lab chillers and circulators we’ve seen over the years. Each of these companies consistently produces items that are durable and cover a range of uses. Lauda Brinkmann offers several levels of chillers and recirculating pumps covering from the laboratory to industrial scale. These include thermostats that can be attached to different vessels allowing users to customize their uses, complete systems, and immersion chillers. They even have process control systems capable of ranging from -150 to 550°C.

Polyscience also covers use cases from benchtop chillers to high-capacity chillers with 33kW of cooling power or systems that cool with a facility’s water supply in a closed loop. High-capacity chillers are built for high-temperature environments with ambient conditions as high as 40°C/104°F. Their benchtop chiller models are ideal for uses like spectrophotometers and rotovaps and feature digital control, powerful pumps, and safety catches to protect subjects and the equipment.

VWR Chillers provide users with a choice of pumps, magnetic drive centrifugal, positive displacement, and turbine, each offering different lift power and compressor capacities that range from ¼ to full horsepower. Using a circulating chiller cuts down on water consumption and is more efficient than tap water cooling. These benchtop systems are also quiet operating, compact and portable, and cool in environments as high as 35°C/95°F.

Thermo Fisher has a catalog full of temperature control solutions, from chillers to immersion circulators, bath circulators, and immersion coolers. Immersion coolers allow you to add cooling to existing equipment by inserting a cooling probe into the application. These can be used to hit a specified target or continually drive toward the lowest possible temperature of -90°C and cut down on the need for fluid maintenance or tap water.

Other reliable manufacturers include Julabo, Cole Parmer, Yamato, Torrey pines, Huber, Ika, Boekel, and Grant. Each company features durable construction, reliable pump performance, and varying levels of digital control.

Final Thoughts

Chillers can offer a degree of control to many applications, from cooling individual vessels, programming slow ramps in temperatures, replacing dry ice, cooling lasers, and more. Which lab chiller you go with will depend greatly on your need, how far you need the circuit to reach, how much heat needs to be drawn off, what the ambient temperature of the room is, and how large an item needs to be cooled.

Over the years we’ve carried many brands, combinations, and sizes of chiller equipment, and we’re familiar with their ins and outs. Our maintenance team knows how to service these useful products to make sure when they reach our site, they are in tip-top shape and have a clean bill of health. Buying a used water chiller can help keep more money in the budget. Let us help you find the right chiller for the task today!