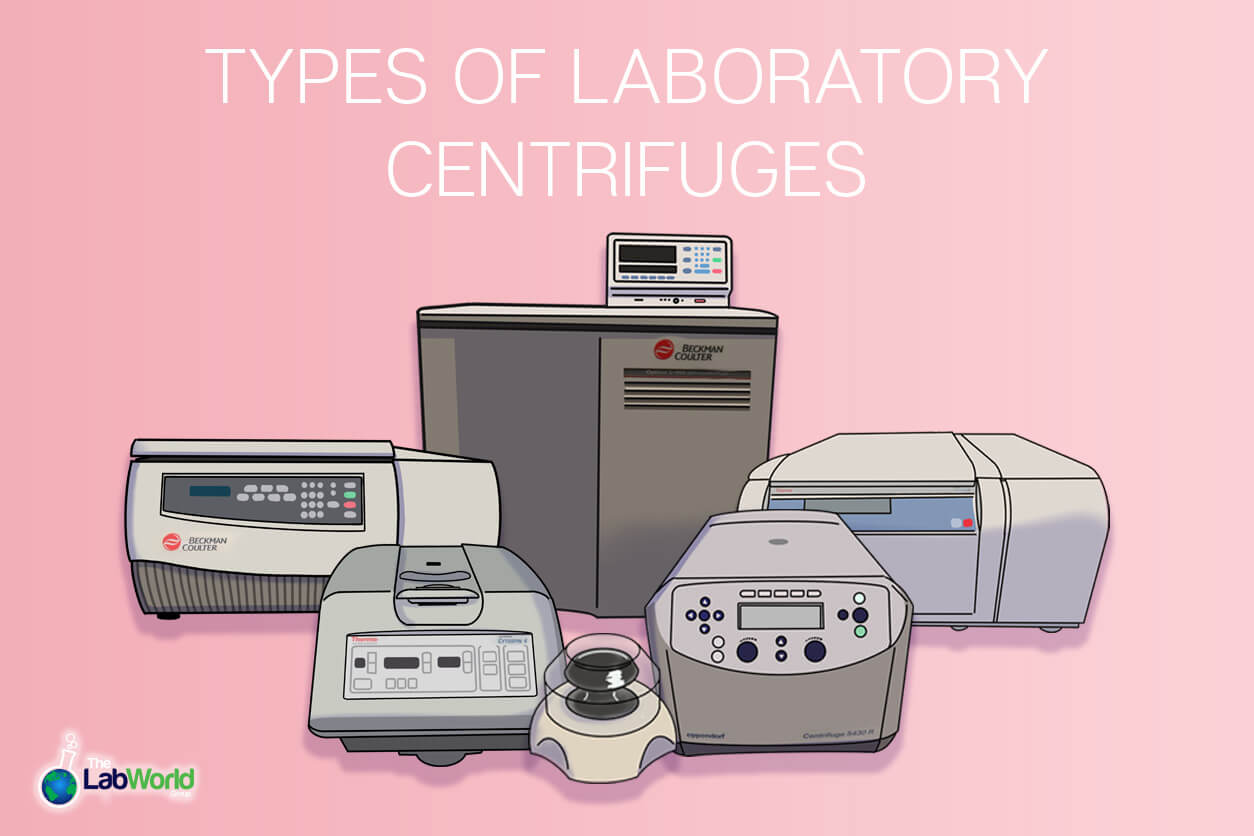

Different Types of Centrifuges

Amanda2022-06-24T13:13:17+00:00Not only do centrifuges span a variety of sizes and volume capacities, but their components can also vary wildly. For each use case and need a centrifuge variation has been developed to solve the problem. Centrifuges with different maximum speeds and force, temperature control, and rotor shape all play a part in how a centrifuge is used in the lab. Here are some examples of how these variables can be leveraged to get the best results.

Centrifuge Speeds

The centrifugation speed needed for separation will depend on the particles in the samples. The smaller a particle the higher the speed that is needed. For simple, routine separations, a low-speed centrifuge is often enough. These compact benchtop models run at under 5000 to 7500 RPM. This covers use cases for chemistry testing or coagulation testing of liquids such as blood or urine, or cellular materials in a clinical laboratory, or with small sample sizes.

High-Speed Centrifuges

The higher speed centrifuges, those above 5000 RPM, are better for higher throughput needs, and larger volumes, and tend to be more multi-purpose. This opens uses up to molecular biology work, preparations for clinical work, and use in industry and quality assurance. High-speed centrifuges can be found in mini capacities, fit on the bench, or could be as large as floor models and can reach speeds as high as 65000 x g. The higher capacity high-speed centrifuges are ideal for labs with multiple users or core production facilities.

Types Of Ultracentrifugation

The king of lab centrifuge speed however is the ultracentrifuge. These models are ideal for very small particles, allowing for purifications, determining molecular weights, DNA preparations, and separating organelles. Ultracentrifugation can spin as high as 1,000,000 x g. When these speeds were first achieved in the early 1900’s it opened a world of discovery at the subcellular level and revealed the building blocks of life. Ultracentrifugation has an extra distinction of uses, these fall either under analytical or preparative centrifugation. Preparative centrifugation pellets small particles, prepping them for use in other lab tasks. Analytical centrifugation is used to determine the properties of a macromolecule, properties such as size, shape, and mass.

Types Of Rotors In Centrifugation

Another component that affects how a centrifuge impacts a sample is a rotor. There are three basic shapes used in lab centrifuge rotors, swing buckets, fixed angles, and vertical. Each of these holds the samples at a specific angle to achieve the desired location of sedimental separation. When you need the sediment at the bottom of a tube, you start with a swing bucket rotor.

The Swing Bucket Rotor as the name describes uses buckets held by hinge joints, set evenly around the center of the rotor. As the rotor reaches its top speed, the buckets are pulled out to 90 degrees from the axis, with heavier particles collecting at the middle of the bottom of the vessel. These rotors have the most flexibility in terms of capacity and vessel shape, this includes microplates. The disadvantage to a swing bucket rotor however is the stress placed on the metal holding the buckets, this translates into a lower achievable g-force and speeds.

When you need higher g-forces, you want a Fixed Angle Rotor. These hold samples usually at a 45-degree angle, surrounded by rotor material. The advantage of a fixed angle rotor is longevity since the construction lacks moving parts, and there’s less stress on the metal or carbon fiber, which allows users to reach higher gravitational forces and higher speeds. This also translates into less processing time, though you’ll need to store a larger library of sizes and shapes if your work calls for variety.

The less common option is a Vertical Rotor, these rotors hold vessels straight up and down during a run, and as a result, a particle has the shortest distance to travel to the side of a vessel. Run times are very short since it takes less time to result, but its use case is highly specialized. Since the sedimentation is spread across the entire length of a tube it’s not useful for pelleting, however, it can be useful for specialized tasks like banding DNA, or gradient and density cushion separations of viral particles.

A variety of Rotor Materials are used in the construction of centrifuge rotors. Historically rotors have been constructed from metal alloys. Aluminum with its low density is ideal for high speeds, however, titanium has greater strength, and is ideal for ultracentrifugation. Metal alloys however will corrode and degrade, fatiguing and stretching over time.

Enter, carbon fiber rotors. These more modern materials have been leveraged in a broad range of fields such as aerospace, military structures, and even sports equipment. A carbon fiber rotor has the advantage of strength, while also being remarkably lighter than its metal counterparts. The bonus of the weight reduction is when loading these centrifuge rotors there’s less risk of damage to the centrifuge and less risk of injury or muscle strain for the operator. Carbon fiber rotors are also corrosion-resistant and are less likely to experience a catastrophic failure. Carbon fiber rotors are a great option for labs looking for long-term solutions.

Why Centrifuge at 4 Degrees

The disadvantage of polymer rotors however is the low thermal conductivity, while this can provide insulation and help keep the temperature even, it also means cooling things down takes time. Aluminum has a higher thermal conductivity which means it could heat faster but a cooling function will be much more effective and rapid.

So why is cooling in a centrifuge needed? The energy expended while spinning at high speeds results in an increase in temperature within the chamber. Depending on what samples are being used, this may not be ideal. Certain analytes are adversely affected by temperature changes; thus the refrigerated centrifuge was introduced to maintain stability. Enzymes, Cells, Hormones, and other Biomolecules need to avoid temperature increases to maintain structure, function, and activity levels.

Final Thoughts

After you’ve worked out your capacity needs, knowing what your performance needs are is critical to picking the right centrifuge for your lab. There are many choices to wade through but we’re here to help. Our selection of centrifuges changes all the time, so if you don’t see what you’re looking for reach out to us, we have more in the pipeline or can help you source what you’re looking for.

Every lab centrifuge that comes through our doors is inspected from top to bottom for integrity and performance so you can count on your new instrument. Let us connect you with the right lab staple that will serve you for years to come.