Futuristic Alloy is as Strong as Steel and Extremely Pliable

While alloys collectively known as ‘metallic glass’ has been around since the 1960s, researchers at the University of New South Wales have developed an ultra-strong, ultra-flexible version that they claim is stronger than steel, yet more pliable than gum, and have also developed a more efficient production process.

So what exactly is metallic glass – and why is this reserach so groundbreaking?

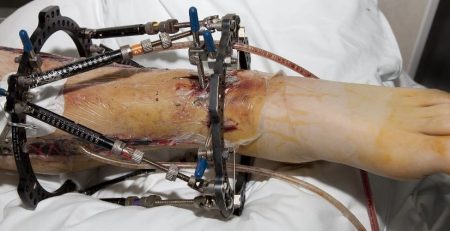

To scientists, glass is any material that can be cooled from a liquid to a solid without crystalizing. When they cool, most metals do crystalize, forming a lattice-like pattern. When crystalization does not occur, the atoms settle in a randomized pattern, giving it very distinctive magnetic and and mechanical properties. Unlike window glass, metallic glass is not brittle, and unlike traditional metals which are easily permanently bent out of shape, metallic glass is capable of springing right back to its original shape. The aforementioned properties make this material ideal for electrical transformers and other similar uses.

To date, manufacturing metalllic glass and other metal alloys had proved to be quite expensive, which is why they are typically only used on high-end products like Swiss watches, and medical implants. The researchers at the University of New South Wales argue, however, that their new computer-based development process will lead to more efficient and cost-effective production of these types of alloys.