History of Bioreactors and Their Uses

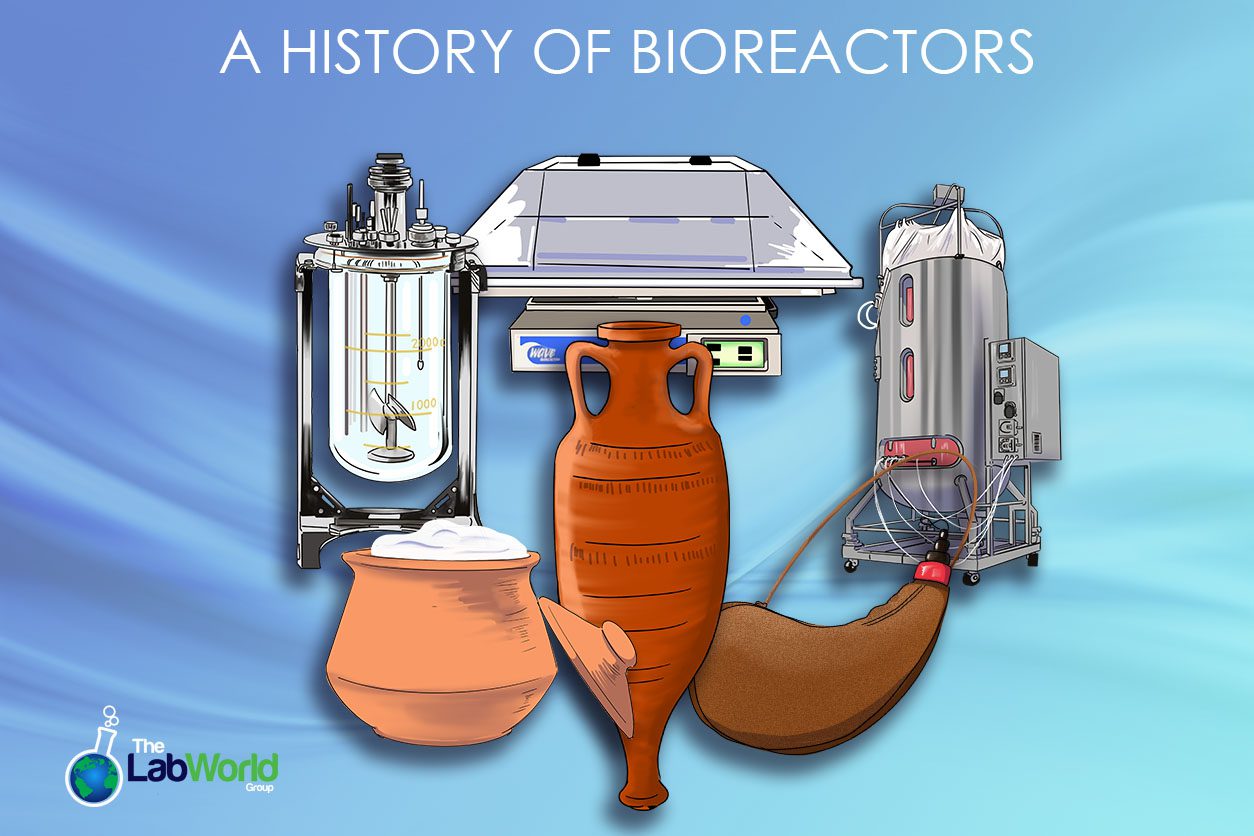

Amanda2024-07-22T16:32:09+00:00When we think of bioreactors, we picture modern-day instruments with shiny glass vessels and digital controls. However, these machines are based on principles developed thousands of years ago and have evolved and changed as civilizations have grown and changed over time.

Ancient humans stumbled upon fermentation, where their milk, juices, honey mixtures, soybeans, grains, and more suddenly changed after being left in a container and exposed to a hot day. Yogurt was accidentally created over 7000 years ago and can be found in most cultures, using milk from cows, goats, yaks, sheep, water buffalo, or other domesticated mammals. Clay pots used to store milk became a bioreactor that encouraged the growth of lactose-loving bacteria that would produce lactic acid, dropping the pH and slowing the growth of harmful bacteria. People at the time didn’t understand what was happening under the hood. Still, they did understand the benefits of what was produced: a better-tasting, longer-lasting product with medicinal properties.

Bioreactors for Beer and Wine

One of the earliest indicators of nonmigratory civilization and technology can be traced back to the creation of beer, wine, and bread. Wine amphoras and animal skins were used to make and store wine using the natural yeast on the grapes, fed by the juice and encouraging fermentation.

Around 5000 BCE, barley-based beer was brewed in pottery jugs in Mesopotamia. Evidence of this can be found in virtually any civilization that domesticated and harvested cereals. It is thought that when grains were cooked to soften them and make them safe to eat, they were left out all day.

Wild yeast in the air consumed the sugars in the grains and produced a fermented product. Cultivating yeast by allowing water and flour to sit brought about leavened bread in Egypt.

Food Fermentation to Preserve

This process of fermentation shows again and again in every culture, like Kimchi in Korea and Sauerkraut in Germany using the yeast on cabbage, and Miso and Soy Sauce made possible by Koji fungus.

This early recognition that heating a food and leaving it to change in a container would encourage fermentation or pickling and curing foods gave two main benefits. Not only would the flavors be enhanced to a new and desirable effect, but it also stored their foods in the days before refrigeration.

Early Civilization and Waste Water Treatment

As humans started to abandon nomadic life and gather in larger groups, storing food became important. When they began gathering in cities, managing disease also became important. Civilizations learned to treat drinking water and wastewater in bioreactors to control the spread of disease, either by exposing it to sunshine or boiling it to make it safe and filtering it through charcoal. They couldn’t have known at the time that microorganisms were the cause of their troubles, but these steps became essential to developing civilization and extending human life.

How the World Wars led to the Industrial Scale Bioreactors and Mass-Produced Penicillin

In 1861, Louis Pasteur developed his Germ theory and proved the bacterial roots of fermentation. Since discovering that bacteria were responsible for some of these beneficial and detrimental effects on our food and health, attention turned to experimenting with their use. Shortly after his discovery, he produced microbial butanol with a mixed bacterial culture that included at least one Clostridium strain. Chaim Weizmann used this strain of bacteria during World War I to produce Acetone. When starches like corn and potatoes are fed, this strain of bacteria produces Acetone, a key component necessary to make cordite or smokeless gunpowder. Until then, the powder was produced with Calcium Acetate from Germany. That was no longer possible with the war, so Churchill commissioned mass production of Acetone through the Weizmann process.

Through rapid wartime expansion, the manufacturing process went from laboratory to industrial scale. This expansion went further during World War II, 21 years later, when there was a considerable need for Antibiotics. Technologies needed to produce penicillin globally opened the door to other bioreactor applications. By 1945, industrial bioreactors could produce 7 trillion units of penicillin.

Bioreactors and Vaccines

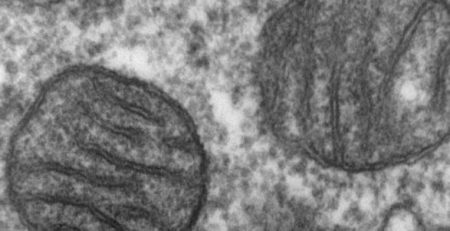

From there, improvements and innovations to the process only grew, including sterilization methods through water, steam, autoclaving, freeze drying, multi-vessel systems to produce multiple products in parallel, and large-volume reactors. In the 1990s, the bioreactor world moved beyond bacteria to grow cells from other kingdoms, such as mammals and algae. Vaccines, including SARS-Cov-2, influenza, and rabies, could be produced on a large scale.

Bioreactors also play a part in the production of life-saving insulin. Thanks to the advent of recombinant DNA, researchers in 1978 could insert the human gene for insulin production into a strain of E.Coli. This Bacteria then started producing insulin, and Humulin hit the market in 1982, saving countless lives worldwide.

Conclusion

As technology and time improve the Bioreactor, we see advances such as single-use containers, more automation, and greater monitoring. The process becomes more streamlined and has greater success rates.

Should your lab require a bioreactor system, there are many out there to choose from. Buying a gently used and vetted system is a great way to ramp up your production levels while keeping e-waste out of the environment. We can work with you to find the right equipment combination to meet your production needs regardless of stage.