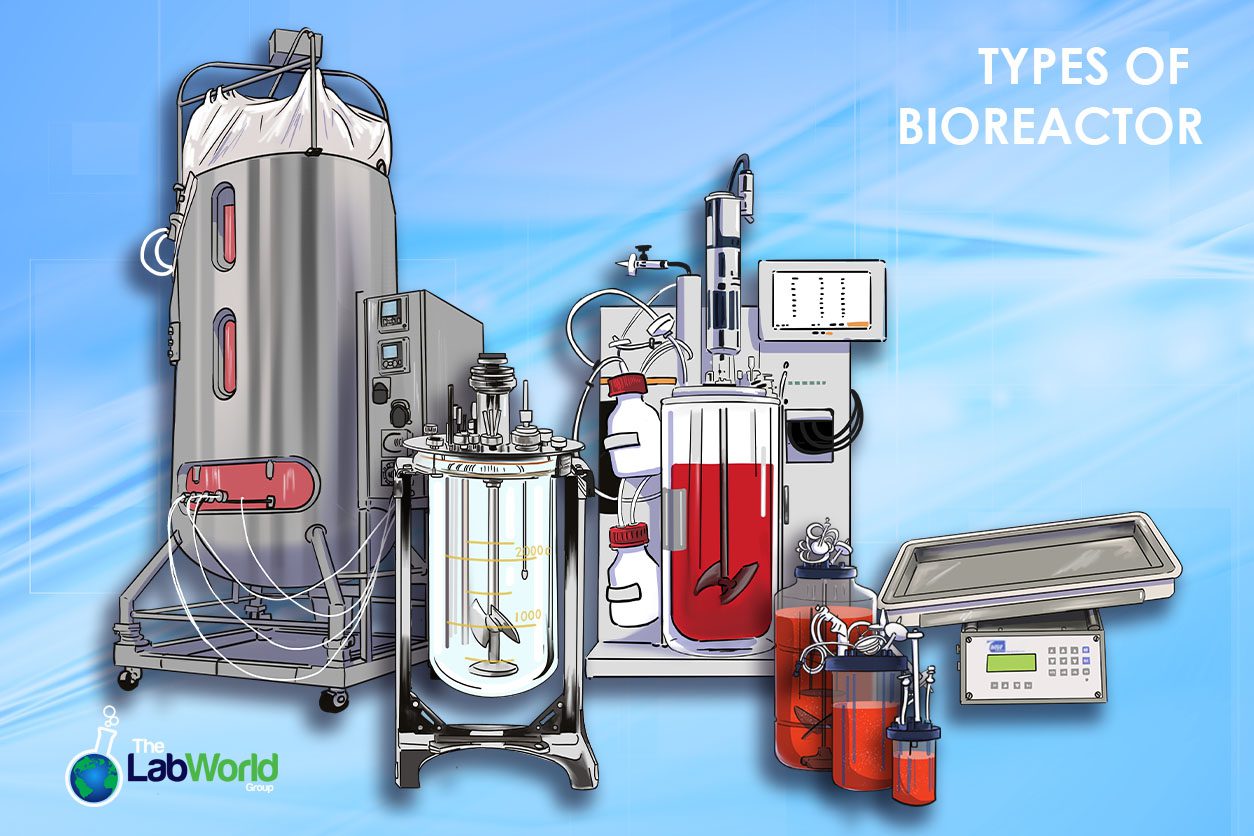

Types of Bioreactors

Amanda2025-03-27T13:30:11+00:00Historically, Bioreactors were mainly jars or animal skins, enclosed and controlled environments where bacteria and microorganisms could flourish. Once scientists uncovered how these reactions were possible and what caused these changes, they turned their attention to harnessing the potential. In the early part of the 21st century, more industrial fermenters and equipment were built, and since then, they have been iterated. Here, we’ll look at modern equipment in labs and industries worldwide.

Anatomy of a Bioreactor

There are many bioreactors, each built for a particular function but essentially consisting of key parts. For example, each requires a tightly sealed vessel to hold the reaction. The vessel can be made of non-reactive glass, stainless steel, and plastic, which resist corrosion and/or pressure. These vessels may include a baffle to prevent vortexes from developing and help improve overall uniformity.

Aerating the bioreactor can be a crucial component. Mixing and aerating can be accomplished either through rocking a mixture, as in the case of a wave reactor, or the case of tank reactors, introducing gas with a sparger, mixing with an impeller, or both. These methods keep the distribution of needed nutrients and oxygen uniform for greater viability. An impeller will also help to reduce bubble size for even distribution.

Next, a method to control temperature is needed, either heating or cooling in the form of a jacket around the vessel or a controlled bath. Temperature control is necessary to create ideal growth conditions, ensure that nutrient supplies are sterile, or remove excess heat produced during fermentation.

Feed ports are an essential part of a bioreactor as they introduce vital factors such as nutrients to feed the cultures or to control pH by adding either acid or alkali to a mixture. These can be contamination vectors, so ensuring they’re sterile is critical. Other environmental factors that require control are managed through monitors. These monitors can control pH, oxygen, or CO2 levels, keeping tabs on cell mass and product concentrations and ensuring enough nutrients.

Types of Bioreactors and Their Applications

A Continuous Stirred Tank bioreactor is the most common choice in industrial applications. They’re easy to clean, simple to operate, and use an impeller to keep media moving and homogenous, with a sparger to aerate the mixture, distributing gas evenly. These systems are easy to control, featuring cooling or heating jackets, pH monitoring, and control to create a largely hands-off system. They require a lot of power, mainly if the culture is viscous and has many moving parts that decontaminate the area between uses. These are ideal for manufacturing antibiotics, citric acid, tissue mass cultures, polygalacturonases, enzymes, etc.

Wave bioreactors/rockers are primarily single-use bioreactors that leverage bags as biocontainers. These systems are ideal for cultivating particularly shear-sensitive cells, as no blades are involved in mixing the media. Instead, the cell bags are placed on a broad platform, and a gentle customizable rocking or wave action is used to mix and aerate the medium. This type is ideal for small-scale tests or pre-production before moving on to larger systems.

Airlift bioreactors or tower reactors are tank-based and feature an internal tube with a gas distributor underneath. The force of the distributor pushes the liquid in the column up, and gravity and force will bring everything down the lower-pressure outer column. This loop keeps the mixtures aerated and homogenous. The simple design and lack of an impeller make this system easy to sterilize and doesn’t require much energy. If the culture is on the dense side, however, circulation is limited, which could lead to insufficient mixing and uneven distribution of nutrients.

A Bubble Column Fermentor is also tank-based but instead uses a gas sparger to create a flow within the system. The gas pressure pushes the media around and mixes in O2 simultaneously. This can be pushed further by adding baffles and perforated plates to help mix and aerate. These reactors are popular in chemical, petrochemical, and wastewater treatment applications.

Fixed Bed Bioreactors are built for adherent cells that only grow on a surface. There are fluidized bed fermentors or packed bed fermenters, depending on the size of the particles necessary. In a fluidized bed, the smaller particles move with the fluid, providing nutrition and better oxygen transfer for the cultures. A fixed bed bioreactor uses a larger matrix of solids, either submerged in liquid or as a flow that trickles through. These are ideal for chemical processing and separation and increase the contact rate of reactants to catalysts. Like all bioreactors, these also have their limitations. A Packed-Bed Fermentor is hard to control for temperature, both in responsiveness and uniformity. A fluidized bed Fermentor makes it challenging to predict the outcome and isn’t the most efficient. Parts also degrade faster, with moving particles wearing surfaces down over time.

Photobioreactors are becoming increasingly popular as attention turns to harnessing the potential of algae and cyanobacteria. These systems are desirable because they only require the power of either sunlight or artificial light. These sources provide energy for the cultures and allow photosynthesis to unfold instead of injecting a food source and oxygen. These tube reactors create environments where oil can be converted to biodiesel fuel or produce pharmaceuticals, fertilizers, and food supplements. The main drawback to these systems is controlling populations of microorganisms that may compete with the algae.

Multiple-Use Bioreactors vs Single-Use Bioreactors

It is essential to keep multi-use bioreactors clean. Any lingering microorganism could ruin your product if left to grow alongside your cultivation, so control through sterilization is critical. Large-format bioreactors require built-in systems like in-place cleaning or steaming systems. Smaller types can be autoclaved to ensure no cross-contamination. Either circumstance can be time-consuming and slow production, but it can also cut down on consumables and waste.

More recently, single-use containers involving gamma-radiated bags and bio-containers placed in reusable hardware were created to cut downtime. These single-use products, which span small to large-scale formats, keep the workflow moving and ensure more favorable outcomes thanks to eliminating cross-contamination. The restriction of single-use bioreactors is due to size limitations. If volume is the game’s name, a multiuse system made of stainless steel that can be sterilized is the way to go.

Conclusion

Understanding the type of cultures you work with is the first step in determining the best bioreactor for the job. Are you developing your process and want to start small? A wave bioreactor might be where you start. Ready to jump into large-scale production? A continuous stirred tank with built-in sterilization may be the answer.

We’ve worked with several lab-scale bioreactors at the Lab World Group, which are ideal for process development and mid-level production. These machines are easy to maintain and operate with the convenience and reliability of a single-use system. Let us help you find the right tool for the job. Contact us today with any questions or requests.