Understanding Parts of a Laboratory Balance and Maintenance

Amanda2022-10-21T22:29:43+00:00What are the parts of a laboratory balance?

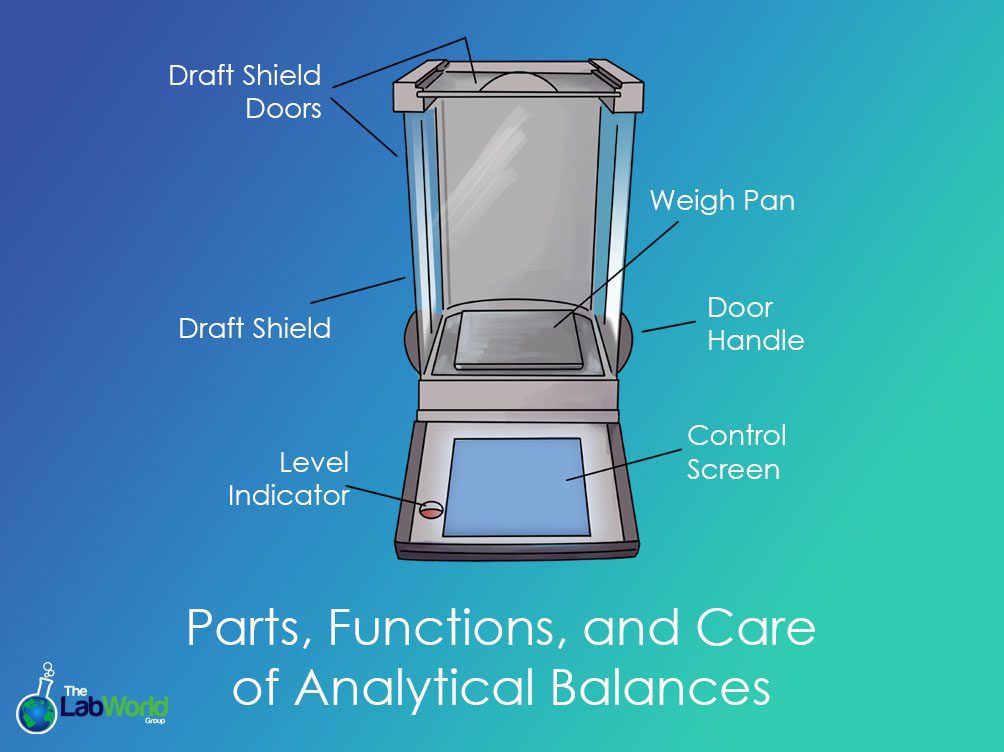

Knowing the parts of your balance and how to maintain the instrument is not only essential for getting accurate reads, but it will also prolong the lifespan of the instrument. Most benchtop digital lab balances have uniform features.

First, up the balance plate or pan, this area holds your objects to be measured. They will sometime be removable for easy cleaning. Weighing can happen directly on the pan or is often the case a weigh boat may be used to hold liquids, or granulated solids and powders. To help minimize the time taken to stabilize, users may consider the smart grid weigh pan that allows turbulence to flow through the pan and speed up your workflow. The weigh pan may also have an anti-draft ring surrounding the pan.

Usually, beneath the weigh pan you’ll find a load cell or force transducer, and most often that will be a strain gauge. Mettler Toledo Balances use monobloc weigh cells, created from a single aluminum alloy block through wire EDM technology with tight margins. This block is constructed from the same alloy as aircraft and has fewer moving parts than traditional blocks, as enjoys a long life of dependable operation.

Keeping it on the level

Leveling feet are an important feature of balance, in conjunction with a leveling indicator or bubble. Having a level balance is critical to a proper reading, so these adjustable legs can be shifted till the bubble, spirit level or plum bob are in proper alignment.

Draft shields in a laboratory balance help to minimize turbulence which can be handy when weighing powders and light items. These are particularly important the higher the readability becomes. Draft shields have access from the sides or the top, with some balances featuring touch-free sensors that automatically open and close the doors.

Lab Balance Display Screens

The control panel and display are situated up front and are sometimes removable in the case of platform scales. This can be useful when working with oversized items and maintaining a clear view of the display. The control panel will present buttons for power, tare or zero to bring the balance back to neutral. Depending on the model, this panel may also include modes or function buttons to toggle through available weighing options like dynamic weighing, parts counting, changing weight outputs, percent weighing, and more. If the lab balance features internal calibration users can recalibrate it with the touch of a button.

Maintaining your balance

When it comes to operating your balance, location and ambient conditions can sometimes present a challenge to collecting accurate data. For one, your lab’s geographical location, specifically its relation to the sea level can impact the gravitation force your sample exerts. To make sure your sensitive and pricey investment is giving you the results you need for years to come, here are some steps you can take for optimal readings.

Location Location Location

Balances need a flat, stable, and level surface to get an accurate reading. For ultra-sensitive balances like an ultramicro balance, this might include extra vibration dampening like an anti-vibration table or slab. These special surfaces are made of shock-resistant materials such as granite, steel, or rubber and help get reading faster, with less interference. Drafts can also impact a reading, so if your lab space doesn’t have a calm area, you can overcome this by placing the balance inside a dead air box or balance enclosure to help safeguard against turbulence.

Ambient Temperature and Measurements

Temperature can also impact measurements, that’s why it is important to allow the scale to warm up after powering on and keep the room within the ambient tolerances set out by the manufacturer. Some balances have internal methods for calibration and compensating for environmental factors, but using a known weight within the scale’s capacity will take care of the job.

Calibrating a Lab Balance

Calibrating your lab scale is an important maintenance step. You should do so, at the very least, once a year, though regularly is better and your field/regulations may require it. You’ll also want to recalibrate any time the balance is moved to make sure you have an accurate result. Some balances include an internal calibration feature, making recalibration as simple as possible, even automatic. External calibration should be done with certified weights that are kept impeccably clean and intact.

Weight on the Scale

One simple thing to consider is the weight on the scale. Avoid overloading the balance or leaving an item on the pan for too long. The internal weight mechanisms for a laboratory balance are delicate and sensitive, with a limited lifespan. That goes for storing items on top of it too or placing it on its side, these can all damage the components over time. That avoidance of pressure also applies to cleaning a balance when you are finished. Gently wiping down with a soft cloth to remove debris and dust helps to keep the lab balance reliably. You should also avoid blowing away dust and debris as this can drive the particulates into the internal mechanism.

Final thoughts

Understanding the part of your balance and how to keep it healthy will extend the life of your investment. Having to replace these lab staples can be costly, and cause interruptions to your workflow, so it’s important to keep them in tip-top shape and to know what parts and accessories can get you the best results.

At The Lab World Group, when a balance comes to use we clean it properly and test it against our certified weights. We also on occasion have accessories such as balance hoods and anti-vibration surfaces. If you have questions, we have answers, tell us what your needs are, and let us guide you to the right instrument and complimenting tools. Contact us today to see how we can help!