University of Glasgow Researchers Develop Cheaper Way to Produce Graphene

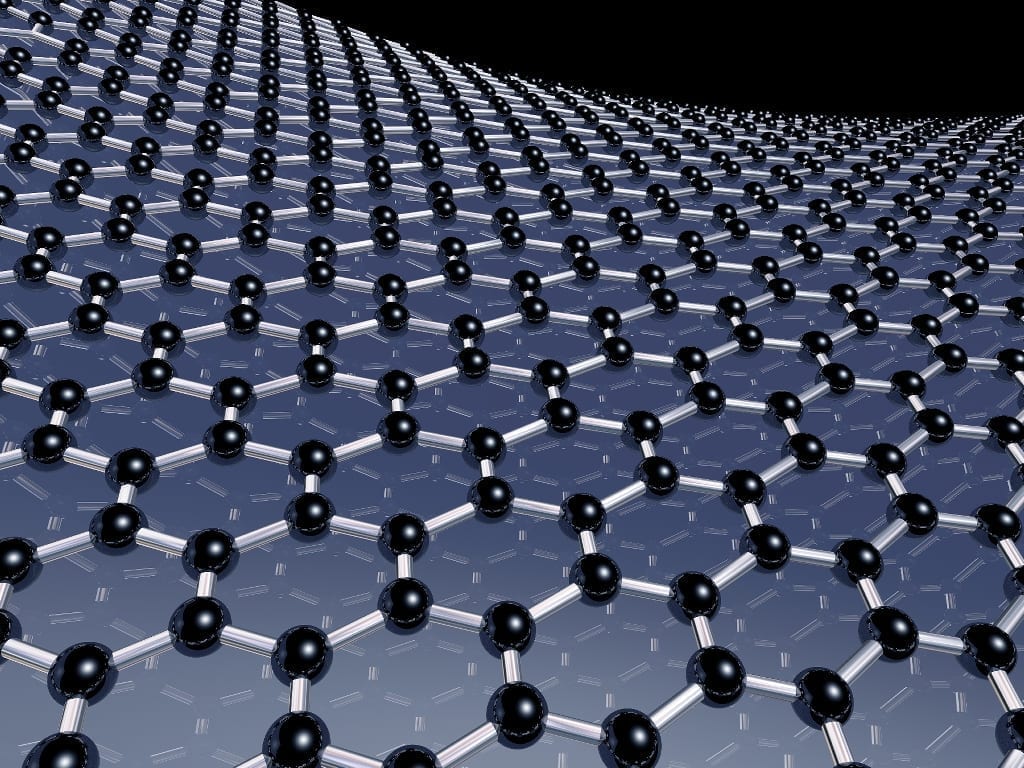

Discovered in 2004, graphene is a variant of carbon. At just one atom thick, the material is light, stong, nearly transparent, flexible and is a great conductor of electricity. It is traditionally produced by way of chemical vapor deposition (CVD), which involves turning gaseous reactants into a film on a special surface called a substrate. The copper used to produce graphene costs approximately $115 per square meter, making it cost prohibitive for many products or potential applications.

A team at the University of Glasgow has found an alternative, however. In a paper published in Scientific Reports, the team outlines how they used commercially available copper foils, like thost used for lithium-ion batteries. The result is a product that is 100 times cheaper to produce, and even exhibited improvements in optical and electrical performance.

The reduction in manufacturing costs “may be intrumental in the introduction of affordable and more efficient electronic devices that incorporate top performing graphene,” The Latest News writes. “Graphene could lead to the production of commercially available synthetic skin capable of providing sensory feedback to people using limb prostheses, a feat that is impossible for even the most advanced prosthetics today.