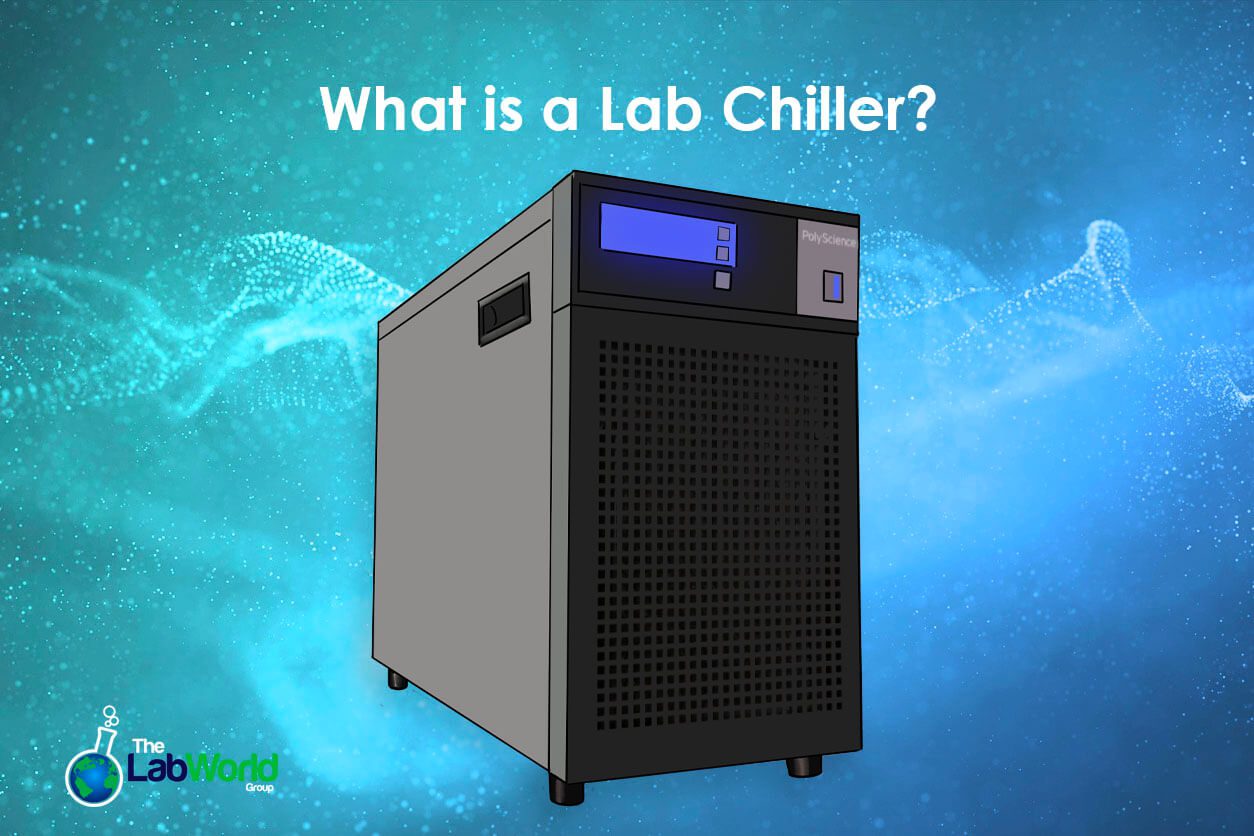

What is a Lab Chiller?

Amanda2023-02-24T15:08:14+00:00What is a lab chiller?

Lab Chillers and Water baths provide laboratories and industry the means to control temperatures, be it in processes, or procedures where things need to remain steady and precise. Either cooling or heating, these lab instruments are built to maintain conditions, sometimes with a very tight margin, evolving over the years from simple boiling water and early artificial refrigeration to digital touch screen control and full horsepower compressors.

For hundreds of years laboratories have used many methods of controlling temperature, with mediums like water being a common choice. A laboratory chiller for example uses liquid, often water to draw heat away from an object, while a heated water bath gently and evenly surrounds an object with heat. At first ice, baths were standard, with 1851 bringing about the first ice machine. Salts could be added to water to depress the freezing point and extend the temperature range but this was hard to control with any precision.

A quarter of a century later Engineer Carl Von Linde discovered the refrigeration cycle and how to efficiently liquefy gasses creating the first reliable ammonia refrigerator. The methods he developed paved the way for the global supply chain of large volumes of gas and more modern refrigeration. This then leads to the first centrifugal water chiller, using a compressor. Over the last 200-plus years, chillers have evolved beyond ice baths adding features like single or double compressors, circulation control, and digital programming.

What are lab chillers used for?

Temperature control in the lab has many uses, from everyday procedures to exacting control requirements to keeping equipment from overheating. Operating above or below room temperature requires a method of control that can be steadily maintained for prolonged periods. One of the most effective and cost-efficient ways to achieve this is a recirculating chiller. Chillers have found a home in multiple fields, not just in the lab, with uses in industries such as welding equipment and machine tooling, airconditioning, dehumidifiers, analytical equipment, or condensing vapors.

Lab chillers help maintain the accuracy of an experiment by eliminating a point of variation. Certain chemical reactions can only take place or may react differently at a set temperature. Not only that but they help to cut down on water waste by conditioning and recirculating the same water, saving tens of thousands of gallons. Lab chillers can be used to quickly drop a temperature of a sample or gently thaw a sample from a deep freeze. Recirculating chillers, water baths, and immersion chillers have applications in chromatography, to help maintain temperatures in reactions, they’re useful in rotary evaporation applications, cooling lasers, and electron microscopes!

What to consider when selecting a lab chiller

Depending on the degree of control you need, some applications are tolerant of a little variation so analog control can be enough. Applications where precise control within a degree is needed, then microprocessor control with feedback monitoring can provide info on not only your set point but the actual temperature and record the process for reporting. It should be noted that while some may think a larger bath will be better at cooling thanks to more available resources, however, this is a misconception. While you do have more cold water to work with, it takes longer to chill, it takes more space in the lab, and will require more power to run it. Instead paying attention to the size of the compressor, pump speed, and cooling capacity will help you zero in on the right chiller for your needs. This helps you keep the workflow snappy, conserve space in the lab, and reduce operating costs.

Final Thoughts

Lab Chillers can offer a measure of control for a broad range of laboratory tasks. In just about any field there is a way to apply this method of temperature control. Figuring out capacity and flow needs it the first step to making a selection from a broad selection of options.

Over the years we’ve carried many instruments at various sizing, cooling capacities, and reach. We’re also very well-versed in their care and maintenance. Chillers listed on our site have passed rigorous testing and are performing at OEM specifications, so you can be sure you’re getting an instrument whose performance is reliable. Let us guide you to the right instrument, and if you don’t see what you need, reach out, we may be able to help source the right instrument for the job.